Having a good understanding of inventory management best practices can help your retail store move stock effectively, leading to increased customer satisfaction and sales. This is especially useful during high demand seasons, such as the start of the school year when music bands require larger orders.

Stocking music instruments and music related products can consume a lot of money, as they require space, can get damaged, or even get lost or stolen. According to The State of Small Business Report, close to half (46%) of SMBs with 11-500 employees don’t track their inventory or rely on manual systems like Excel. This is why it becomes critical to use the proper procedures and softwares to track inventory, to track your items from the moment they arrive at your store until they are sold. In this article, we will see how you can use 5 inventory management protocols to help your business succeed.

- Determine which costing method suits your operations:

It’s important for small business owners to identify which costing method will suit their operations best. This decision will determine what cost will be assigned to an item when you sell it in order to calculate your profit margins. Here are the facts about each option:

- FIFO: First-In-First-Out (FIFO) method of inventory valuation is easy and accurate. The method is based on the assumption that the products which are purchased from the supplier (or produced) earlier are sold first. So, the FIFO method takes the cost of the oldest inventory as a basis of COGS (Cost of Goods Sold) formula.

- LIFO: The Last-In-Last-Out method is the opposite to FIFO. It assumes that the most recent products are sold first. Under the LIFO method, the inventory that was acquired first remains on the company’s balance sheet while the newer items are being sold. The LIFO method is used commonly in the US, as it is acceptable under the GAAP regulations.

- WAC: The WAC inventory valuation method stands for Weighted Average Cost. Under the WAC method, a retailer estimates a weighted average by dividing the COGS (Cost of Goods Sold) by the number of items available. So, the retailer can then have the actual picture of inventory available on hand, an average between the newest and oldest products.

2. Implement a counting cycle program:

To efficiently manage your inventory, you’ll need to put a system in place. When deciding on a counting cycle, keep the following in mind to make sure it best meets the needs of your business:

- Frequency: What is the optimal number of counts your team can complete each year, and how will cycle counting affect warehousing, receiving, and delivery?

- Strategy: Once you have determined the frequency, consider dividing inventory into categories such as locations, items, or values.

- Supervision: Select a reliable employee to oversee inventory counting processes.

3. Evaluate your inventory levels:

The inventory levels of your small business should be monitored carefully in order to ensure profitability and a steady cash flow. Having too much stock can be detrimental as it increases operating costs and limits your ability to make informed decisions.

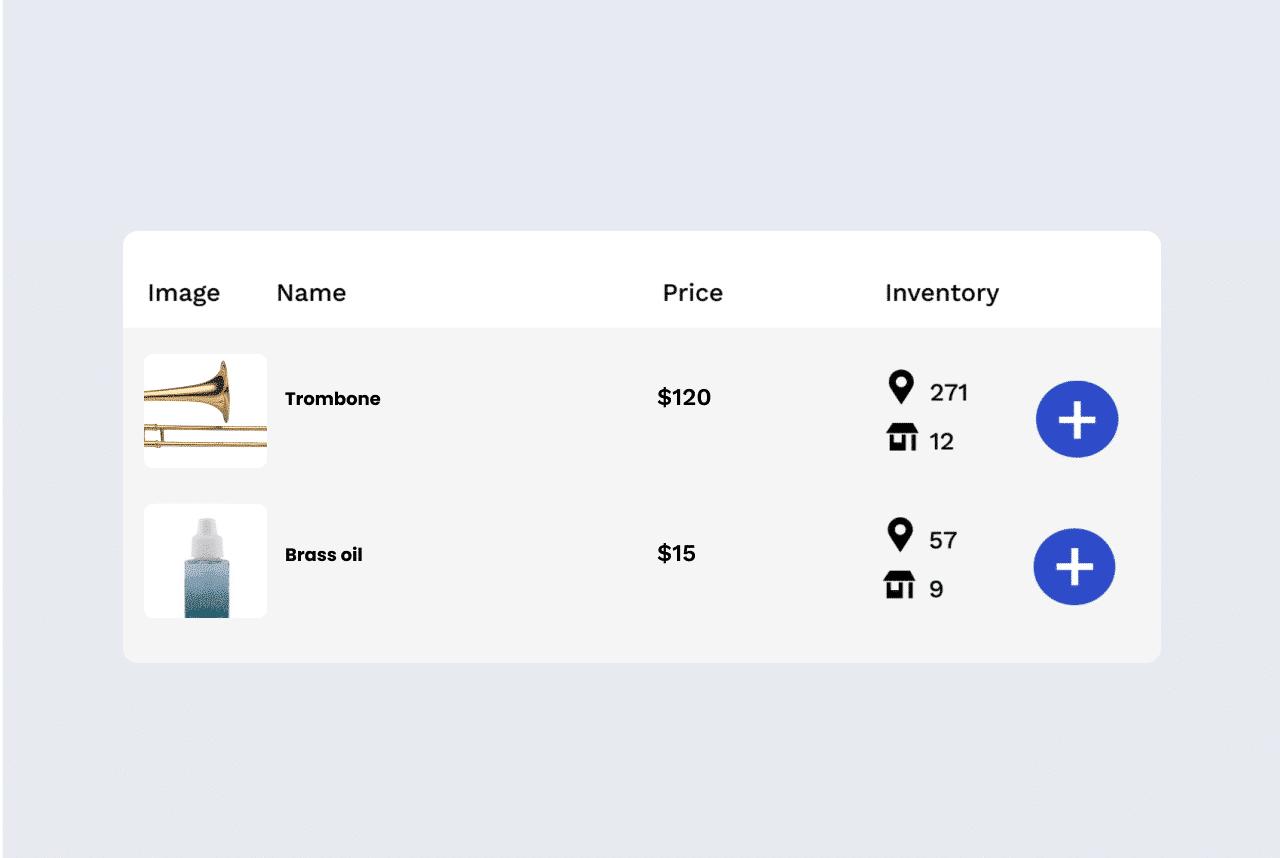

Using an inventory management software can really help you accurately estimate required stock levels for each product. Additionally, it allows you to keep track of important data like sales patterns and turnover history, helping you make smarter business decisions.

4. Include quality control measures into your operations:

No matter your business size, having a quality control system in place is essential for customer satisfaction and business growth. This means setting up a checklist of criteria to evaluate your products for any damage or discrepancies in terms of style, color, size, and price.

It’s important to make sure that all team members are working towards the same goal of providing quality products for customers. Make sure employees have been properly trained to identify and return products that don’t meet the necessary criteria. Additionally, check that the environment of your storeroom or warehouse is free from conditions that could damage goods, such as excessive lighting, moisture, or temperature.

5. Optimize inventory levels to meet customer demands:

When you implement effective inventory best practices, you’ll be able to optimize stock levels and meet customer demands. In today’s digital marketplace, customers are quick to spread any negative experiences they encounter with your brand, and they won’t hesitate to find another company if you can’t deliver.

It’s essential to have inventory optimization strategies in place for your business’s long-term success. This will reduce the chances of losing customers, having to cut down on inventory levels, and shrinking the size of your workforce.

Prioritizing inventory management is key to mitigating any inefficiencies in your operations, as well as being better prepared for the future. Investing in your inventory management systems is a smart move and will help ensure your business continues to thrive.

Inventory management best practices are essential for music stores to ensure their growth and success. By implementing these practices you will reduce expenses, streamline your operations, and maximize customer satisfaction – all of which are key in today’s competitive retail space.

If you’re interested in seeing how QuoteMachine can help you implement these best practices, don’t hesitate to book a free demo with one of our specialists.